Wong says that the procedure continues to be evaluated for filling a monoclonal antibody As well as in exploratory research for vaccines. He says that numerous applications, starting from early- to late-phase clinical, are making use of the procedure.

It’s generally advisable to research and phone the manufacturers right for quite possibly the most up-to-day info on BFS equipment availability and specs.

Uncover how to simplify installation, provide adaptable positioning and change the drive in your air knife.

QbD introduces a systematic approach to pharmaceutical improvement and manufacturing,pinpointing and defining proactive targets for production processes. Scientific actualities and high-quality possibility administration Incorporate to make sure whole idea of the item and process to ascertain significant controls to be sure products top quality.

BFS has very long offered modern Major packaging methods for sterile respiratory and ophthalmic items, and helped these markets change from filled glass containers to plastic.

Hartzel (Catalent): Lately, there are actually many improvements, as an example the introduction of the filling technology that can decrease particulates, and Increased temperature controls of the process formulation. Although the accurate innovation has revolved all-around leveraging the BFS technology to build superior Main offers that finally support clients and caregivers. The market is gaining a far better knowledge of how and where BFS fits into Main packaging layout as well as processing of aseptic items. The foremost technology improvements lie in organizations Making the most of the true value of BFS as an advanced aseptic producing process that automates the development and filling of a Main container closure.

The filling chamber over the BFS procedure is isolated within an ISO-5 surroundings, as well as effectiveness of BFS allows for manufacturing strategies being fulfilled with responsible good quality no matter container dimensions or quantity.

“These parameters are from details all through the production approach, from the bulk merchandise in the holding tank to the final sealing from the BFS container. The purpose would be to optimize the conditions to deliver the most effective amount of Handle.”

These adjustments have produced an enormous impact on the packaging business and You can find an ever-increasing require to supply tailored, unique packaging options, which assure the efficiency of medicines.[four]

Forming, filling, and sealing of containers takes place in a continuous ribbon of parison flowing round the needles.” The skin ecosystem will likely not impact the item so long as the parison is functioning.

We are actually delivering high-good quality products to individuals for just about thirty a long time. We have been devoted to frequently Checking out means to boost our amenities, our individuals, and our processes, with the final word intention of helping more individuals.

Which has a rich history and ongoing progress, BFS technology has grown to be the go-to check here choice for numerous corporations in search of to make sure the best levels of products security and high quality.

Each individual Assembly contains displays on an array of BFS linked subject areas by major marketplace gurus (each operators and suppliers). Members get to hear shows on the most recent developments in BFS associated technology and best tactics. The conferences also often involve a tour of 1 of our member’s web sites which always proves very popular and insightful.

e., the ApiJect Prefilled Injector) produces a whole new variety of scalable and price-efficient prefilled syringe. We believe that in the future, BFS drug shipping and delivery programs similar to the ApiJect Prefilled Injector will become an increasingly well-known format for injectable medicines, increasing use of blow fill seal in pharmaceuticals the overall prefilled syringe marketplace and producing these huge capital investments a sensible business enterprise conclusion.

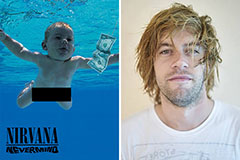

Spencer Elden Then & Now!

Spencer Elden Then & Now! Taran Noah Smith Then & Now!

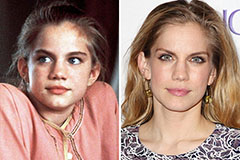

Taran Noah Smith Then & Now! Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! Kelly McGillis Then & Now!

Kelly McGillis Then & Now! Erika Eleniak Then & Now!

Erika Eleniak Then & Now!